This Flying-V Airliner Was Designed By A Student And It Will Use 20% Less Fuel

Air travel is one of the biggest factors when it comes to pollution. It is considered to be the most harmful traveling option and despite various claims to be “eco-friendly”, most aviation companies have a long way to go when it comes to sustainability. Currently, we are in such a position that the most sustainable way of traveling by plane is, well… not flying at all and instead, taking a train. But hopefully with today’s current technology, we will find new ways to save the environment and be able to travel. Engineers at the Delft University of Technology are working hard to make this possible.

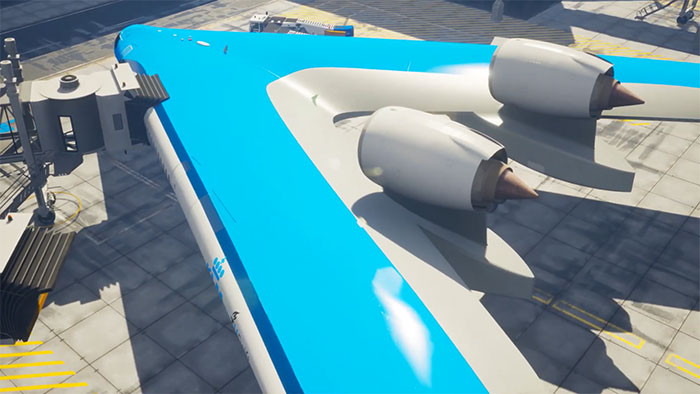

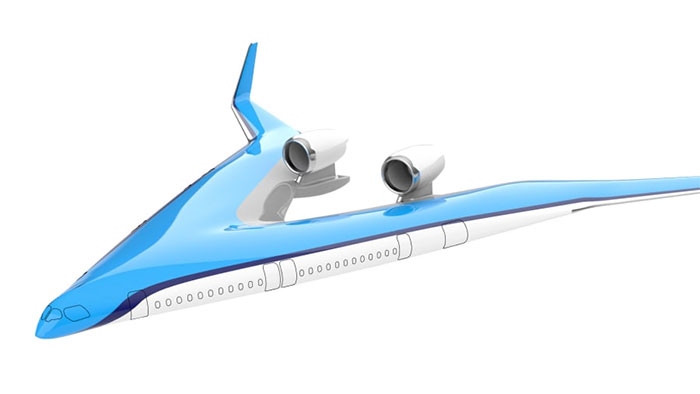

The aerospace engineering team is working on a new airplane model that might change air travel for good

Image credits: Edwin Wallet, studio OSO

Dutch airliner company KLM is contributing to the research of this new airplane prototype that is being constructed at the Delft University of Technology (TU Delft).

The first prototype of this plane was conceptualized by TU Berlin student, Justus Benad

Justus created the concept for his project regarding potential aircraft designs for the future.

The aircraft is named after the iconic Gibson flying-v electric guitar

Iconic artists like Jimi Hendrix, Brian May, and Keith Richards used to play it.

It is believed that the plane would burn up to 20% less fuel

Which is a very important environmental factor considering current aviation contributes to around 2.5 percent of global CO2 emissions.

The first test flight is expected to happen this September and the actual plane should be released around the year 2040

The plane will be able to carry 314 passengers and they will be seated in the wings along with fuel tanks and cargo.

Watch the video to learn more about the design of this plane

161Kviews

Share on FacebookJust like concept architecture & concept cars, only a very minute percentage will make it into real production. While this is a great idea, 20% less fuel is something the world could use right NOW. Unfortunately with a "supposed" timeline of 20 years(!!!!!)..... well, you know.... :-/ This offcourse being a good idea, it is highly likely within the coming 5 - 10 years this idea has been surpassed by numerous other more practical & actually feasible initiatives with better fuel reduction results. From a marketing & PR perspective this is just a brilliant & cheap manner spreading KLM innovation propaganda ;-)

There is a solution that can minimize the amount of fuel taken on board (less fuel on board - less heavy plane, saves the planet) - by weighing all the passengers and hand luggage and calculating based on that how much is needed. Quick way, easy enough, can be done NOW. (and please let smart people continue to think up more ways) - but.. was shot down because people do not want to be weighed and claimed privacy...

Load More Replies...This design introduces a whole lot of issues, not necessarily insurmountable, but serious none the less. Because of the distance the outermost passengers will be sitting from the roll center of the airplane, traditional airliner outmaneuvers and as a consequence landing, holding, missed approach patterns wouldn't work because the outermost passengers wouldn't experience rolls as a roll, they'd experience them as a drop or rise. By law a normal 30 degree roll for an airliner must be able to return to level attitude in 7 seconds during landing and 5 seconds during takeoff, 30 degrees in 5 seconds is a turn rate of 8 degrees per second. If you were at the back outside seat you would feel a roll like that as a fall or rise of nearly 17 feet at an average of 4.45 feet per second to comply, pretty violent and more then sufficient to make someone sick. Normal maneuvers wouldn't be so violent but they would still be extremely uncomfortable, new approach/departure paths would be needed.

It’d also make it so that balancing the load weight on the plane side to side is both more difficult and more important.

Load More Replies...The title is a little misleading. KLM, like all major airlines, is not in the airplane building business. I suspect that KLM is helping with research funding for modeling, and maybe even for scale prototypes for wind tunnel testing as part of the Engineering school research. The actual integrated plane design would need to be done by an entity with more comprehensive ability such as Airbus, Boeing, etc.

Just like concept architecture & concept cars, only a very minute percentage will make it into real production. While this is a great idea, 20% less fuel is something the world could use right NOW. Unfortunately with a "supposed" timeline of 20 years(!!!!!)..... well, you know.... :-/ This offcourse being a good idea, it is highly likely within the coming 5 - 10 years this idea has been surpassed by numerous other more practical & actually feasible initiatives with better fuel reduction results. From a marketing & PR perspective this is just a brilliant & cheap manner spreading KLM innovation propaganda ;-)

There is a solution that can minimize the amount of fuel taken on board (less fuel on board - less heavy plane, saves the planet) - by weighing all the passengers and hand luggage and calculating based on that how much is needed. Quick way, easy enough, can be done NOW. (and please let smart people continue to think up more ways) - but.. was shot down because people do not want to be weighed and claimed privacy...

Load More Replies...This design introduces a whole lot of issues, not necessarily insurmountable, but serious none the less. Because of the distance the outermost passengers will be sitting from the roll center of the airplane, traditional airliner outmaneuvers and as a consequence landing, holding, missed approach patterns wouldn't work because the outermost passengers wouldn't experience rolls as a roll, they'd experience them as a drop or rise. By law a normal 30 degree roll for an airliner must be able to return to level attitude in 7 seconds during landing and 5 seconds during takeoff, 30 degrees in 5 seconds is a turn rate of 8 degrees per second. If you were at the back outside seat you would feel a roll like that as a fall or rise of nearly 17 feet at an average of 4.45 feet per second to comply, pretty violent and more then sufficient to make someone sick. Normal maneuvers wouldn't be so violent but they would still be extremely uncomfortable, new approach/departure paths would be needed.

It’d also make it so that balancing the load weight on the plane side to side is both more difficult and more important.

Load More Replies...The title is a little misleading. KLM, like all major airlines, is not in the airplane building business. I suspect that KLM is helping with research funding for modeling, and maybe even for scale prototypes for wind tunnel testing as part of the Engineering school research. The actual integrated plane design would need to be done by an entity with more comprehensive ability such as Airbus, Boeing, etc.

254

48