Boss Punishes Employee Because His Work Is Perfect Only 99% Of The Time, Regrets It After He Reaches 100% With Horrible Productivity

InterviewIn life, you can’t always have it all. If you want to get a good night’s sleep every evening, there will be times where you have to sacrifice your social life. If you want to excel in your career, you’ll likely have to choose between a thriving social life or getting enough rest.

For a job well done, it’s usually important to consider the quality and quantity of your work, but you can’t focus on them both equally. Quality might seem like the most important factor, but when you’re getting paid to complete a task in a timely manner, you don’t have the luxury of taking all the time in the world. One welder on Reddit understands finding the balance between these two important q’s, but his boss, on the other hand, seems to want to have it all: extreme efficiency and accuracy.

Below, you’ll find a story the welder recently shared online detailing how he maliciously complied to his boss’ demand to work 100% accurately, as well as an interview with the welder himself and some of the responses amused readers have left on his post. Enjoy checking out this story, pandas, and then if you’re interested in reading another Bored Panda article featuring malicious compliance in the workplace, look no further than right here!

After being called out for not working 100% accurately, this welder decided to maliciously comply with his boss’ demands

Image credits: Naval Surface Warriors (not the actual photo)

Image credits: Arctic Warrior (not the actual photo)

Image credits: u/Ok_Present_6508

It’s no secret that when asked whether quality or quantity are more valuable, most people will deem quality more important. Would you rather have 5 slices of cake from the grocery store or one delicious, fluffy and fresh slice from a local bakery for the same price? Would you rather have 10 poorly made paintings or one masterpiece? Would you rather have a sturdy, well-constructed couch that will last a decade or have to go through 4 cheap ones that inevitably fall apart within the same amount of time?

Even employees report that their job quality matters more for their mental health than the number of hours that they work, according to a study by the National University of Singapore, University of Salford, University of Cambridge and University of Leeds. “Our results suggest that there is no ‘optimum’ number of working hours at which employees’ mental health is at its highest,” said Dr Senhu Wang, Assistant Professor at the National University of Singapore and lead author of the report. “Instead, doing meaningful and useful work, having a positive relationship with colleagues and low work intensity are particularly important for employees’ mental health.”

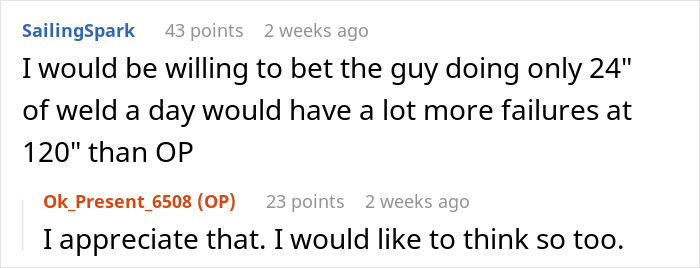

However, in this particular case on Reddit, the welder was still working incredibly accurately, while managing to do 5x the amount of work as his colleague. We all know that the chances for error will increase the more work an employee takes on, but making mistakes 1% of the time does not seem like anything to be concerned about. Especially considering that the OP noted he would always correct any errors by the end of his shift, so he was never wasting time or materials.

To learn more about this specific situation, we reached out to the welder himself, Reddit user Ok_Present_6508, who was kind enough to have a chat with Bored Panda. He shared that this story actually took place roughly a decade ago, but he recently subscribed to r/MaliciousCompliance and enjoyed reading the stories, so he decided to join in on the conversation.

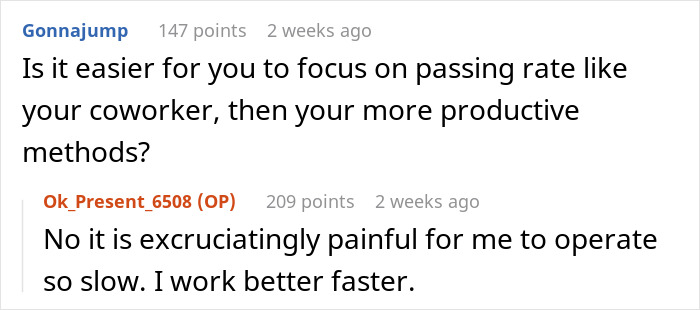

We were curious if Ok_Present_6508 ended up returning to his regular quantity of work following this whole debacle. “I did increase my productivity again. It still amazes me how many people on Reddit still don’t understand that 1% failure, that is repair and passed by the end of the day, is still a 100% pass rate,” he shared.

“The coworker in question was actually pretty lazy and spent a lot of time off task. My pass/fail rate was still pretty above average for the shop and on par with the guys working swing shift,” he went on to explain.

The welder later responded to a few questions from curious readers who were amused by his story

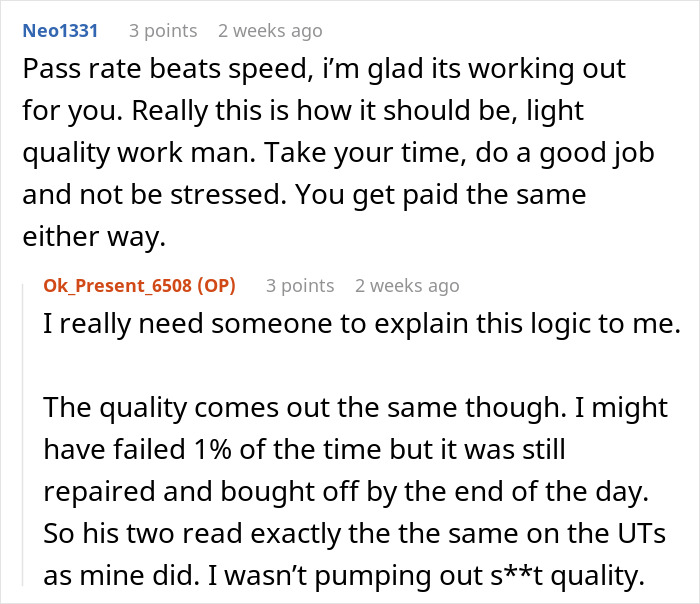

We also asked if the foreman learned anything from this experience. “He did learn his lesson. He, of course, wouldn’t admit that, but I started being able to pick up some overtime on the job,” Ok_Present_6508 told Bored Panda.

But unfortunately, that wasn’t the reward his past self thought it was. “That foreman was kind of full of himself,” he explained. “His work area had ‘inspirational’ quotes posted up around his area that he quoted himself, if that makes sense. For example, it would say something like, ‘Opportunities don’t happen, you create them.’ – D. [his last name] like that. I wish I could remember some of them, but they were eye-roll worthy.”

We also asked Ok_Present_6508 why it’s important for bosses to listen to their employees concerns and understand where they’re coming from in situations like this. “I think it’s important that every employee gets the opportunity to work overtime,” he told Bored Panda. “It sucks, but the money is cool. Trying to make it seem like an exclusive club sends the wrong message about it. Nobody should want to work overtime, and employers shouldn’t make it seem like something they want you to work either.”

“And obviously, trust is a two-way street,” he added. “If your boss doesn’t trust you, then your subordinates aren’t going to reciprocate that trust. It just causes unneeded tension.”

“That’s something I’ve learned over the last 19 years in my career: treating your employees like they’re people, and showing them respect and kindness goes a long way,” Ok_Present_6508 shared. “We’re all here at work together for the majority of our lives. I don’t go home and be a [jerk] to my family, so why should I be [jerk] to the people that I spend so much time with!”

We would love to hear your thoughts on this situation in the comments, pandas. Have you ever had to deal with an employer who wouldn’t listen to your concerns? Feel free to share any of your personal stories down below, and then if you’re interested in checking out another Bored Panda article featuring malicious compliance in the workplace, we recommend reading this story next!

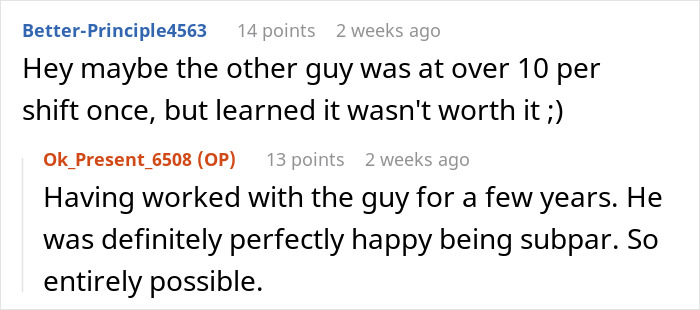

Not everyone was on this employee’s side though, as some readers were a bit more critical with their responses and queries

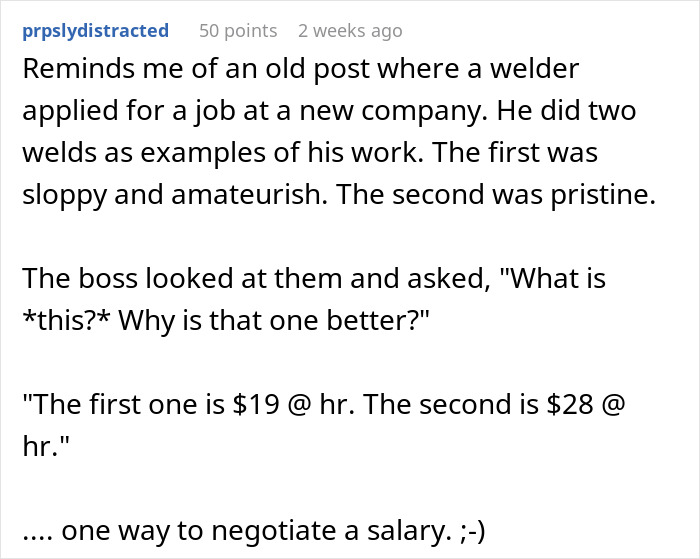

Some people even chimed in with similar stories from their own workplaces

Ultrasonic inspector for over a decade here. I'll toss my 2 cents in the ring because my career never comes up this organically. This welder is lucky he kept his job. I have worked in many weld shops and field weld positions as the inspector and in probably 90 percent of those shops, they had rework limits for welders. From pipeline where 2 failed welds in a week bought you walking papers, to the worst fab shop I worked in where they just hated it because the customer got repair reports. Grinding and back gouging with an arc gouge risk damaging the part. Repair limits can mean you've over ground and the part is now not repairable. Weld prep is designed for stress and repairs change that weld prep shape and can leave stress outside the design within the part. Welders are always told no repairs are better than just a couple. This is a very young or new welder.

Also because I saw it in his reply UT was being used as a precheck for xray. This is common as they excel at finding slightly different problems and both will identify larger issues. Because UT didn't make a record they are allowing repair prior to Xray. If they didn't consider it a precheck but instead added an encoder and created a record failing UT would be a "big problem" as it is if its caught in xray. So again I say fortunate that shop allowed repairs without calling them failed welds.

Load More Replies...Ultrasonic inspector for over a decade here. I'll toss my 2 cents in the ring because my career never comes up this organically. This welder is lucky he kept his job. I have worked in many weld shops and field weld positions as the inspector and in probably 90 percent of those shops, they had rework limits for welders. From pipeline where 2 failed welds in a week bought you walking papers, to the worst fab shop I worked in where they just hated it because the customer got repair reports. Grinding and back gouging with an arc gouge risk damaging the part. Repair limits can mean you've over ground and the part is now not repairable. Weld prep is designed for stress and repairs change that weld prep shape and can leave stress outside the design within the part. Welders are always told no repairs are better than just a couple. This is a very young or new welder.

Also because I saw it in his reply UT was being used as a precheck for xray. This is common as they excel at finding slightly different problems and both will identify larger issues. Because UT didn't make a record they are allowing repair prior to Xray. If they didn't consider it a precheck but instead added an encoder and created a record failing UT would be a "big problem" as it is if its caught in xray. So again I say fortunate that shop allowed repairs without calling them failed welds.

Load More Replies...

62

5