One Of The World’s Last Remaining Globe-Makers That Use The Ancient Art Of Making Globes By Hand

In the modern age, with the advent of GPS in addition to the abundance of mass-produced globes and maps, the art of globe-making has seemingly long disappeared. Only two workshops in the world still make modern handcrafted globes; one of them is us….. Bellerby & Co. Globemakers, a studio based in London, England.

Our studio began in 2008 when Peter Bellerby struggled to find a quality globe for his father’s 80th birthday present. Faced with a choice between cheaply made modern globes or fragile, expensive antique reproductions, Peter decided to try and make his own. The process turned out to be more complicated and costly then he imagined. After two years of trying to create the perfect globe, Peter turned this newfound passion into an artisan business.

We now have a small team of dedicated Globemakers constructing high-quality, handmade, terrestrial and celestial globes. With bespoke cartography, each globe is made to order and essentially one-of-a-kind. From the various bases, to the painting, to the mapmaking, each piece is expertly crafted in-house using both traditional and modern techniques. We ship worldwide and undertake bespoke commissions of all sorts.

More info: bellerbyandco.com | Twitter | Instagram | Facebook | Tumblr

It takes each new team member at least 6 months of practising and learning to make a globe

Shading around the coastlines on a 50cm globe.

I figured out how to create globes by trial and error

It took a long time to make one that was perfectly balanced and approx. 2 years before I produced a globe that I could sell. (Photo by Stuart Freedman)

Favourite part? Putting on the last gore

It is an immense feeling of pride and you can stand back and admire what has taken so long to complete.

Peter hopes his skills can be passed down within his family

Jon, adding detail to an 80cm globe.

Gores with one layer of paint added

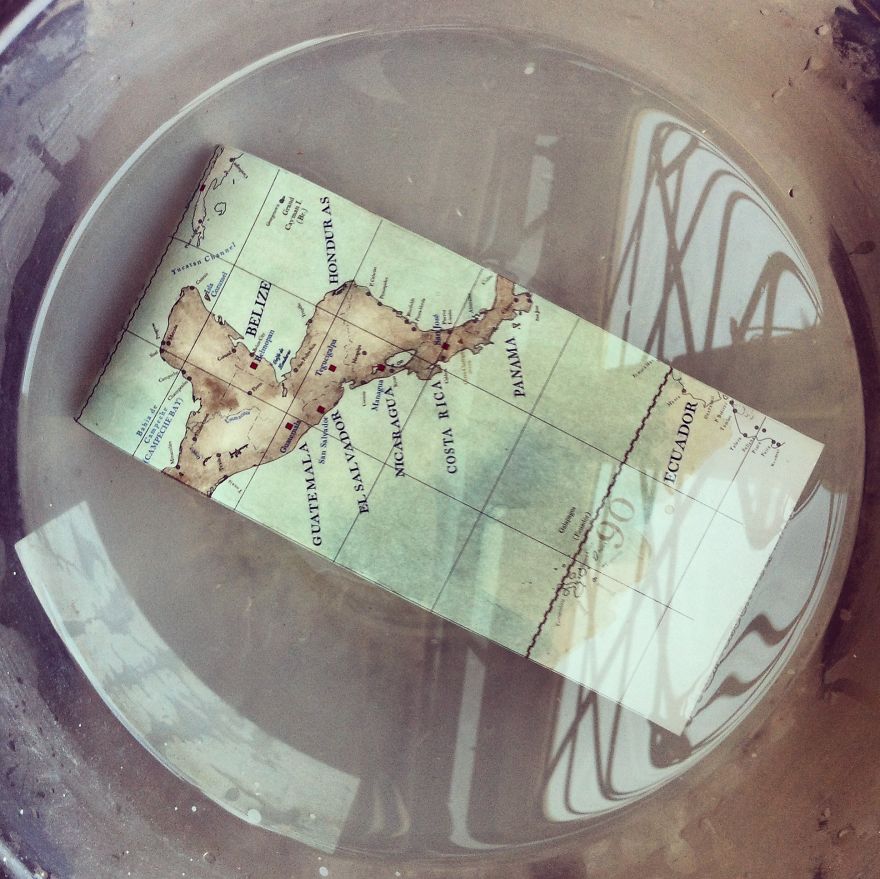

We have to make multiple sets of gores matched in colour, if the wet paper is ripped or torn while it is being stretched, it can then be replaced with another perfectly matched gore

Adding a tiny illustration of a polar bear

I feel like people are turning away from a throw-away society where you can get everything quickly but it soon falls apart.

One of the challenges in globe making is the fight with Pi – if you don’t constantly measure and re-measure, you will be unable to complete the process

Section of the world in water

This piece of paper is called a gore, it is left in water for just the perfect amount of time before it is then stretched and manipulated onto a sphere without tearing or overlapping

Painting Scotland

We all love what we do and are happy to come to work everyday, i don’t think many people could say that of their jobs and we realise we are very lucky.

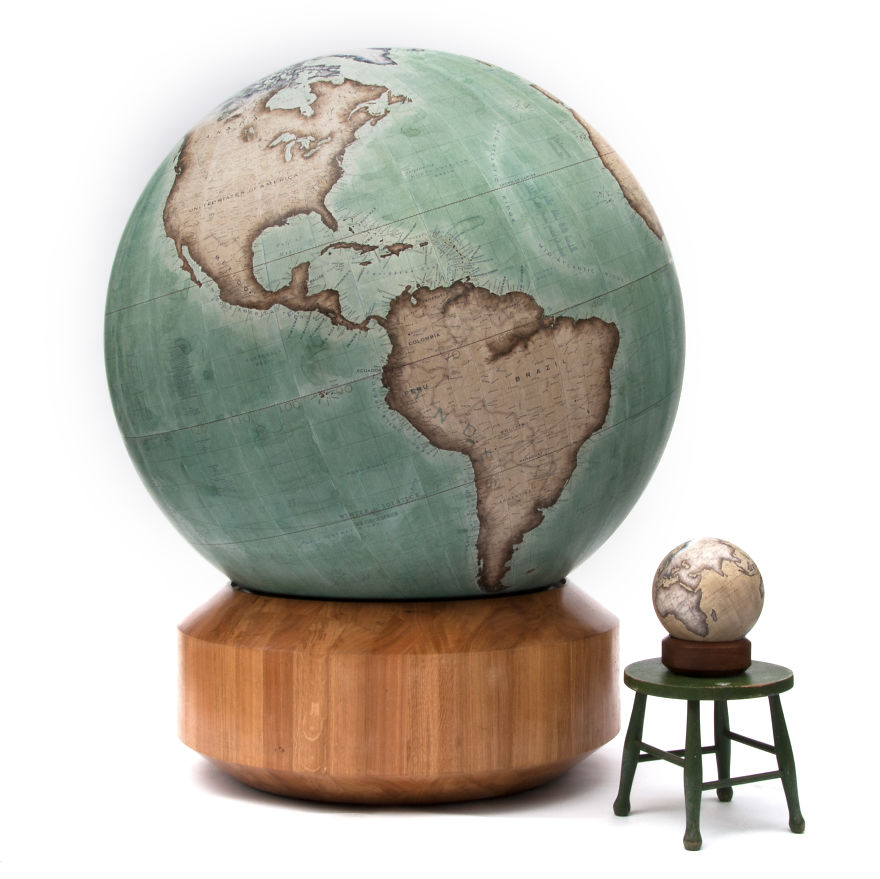

Our largest globe… the 127cm Churchill

What does it take to be a globemaker? Incredible amount of patience and the ability to re-train your body

You have to re-train your body in a almost tai-chi manner to do everything with great control and precision.

Isis started painting around the coastlines in England and is working her way around Cambodia, Vietnam & towards the Americas

Our office dog George and some finished globe behind him

Halfmade World

An 80cm world globe in progress, the first half of the gores must be laid perfectly before the second half can be matched up on the other hemisphere

These strips of paper have been expertly cut & a first wash of paint has gone on, they can now be laid & stretched onto a sphere to form the perfect world!

We are attempting to make our globes aesthetically beautiful and that is never going to be achieved by colour print out. The depth that is achieved by adding layer upon layer of pigment is only possible through this lengthy process….. and it is immensely worthwhile.

Listening to music while painting the first wash of colour onto large gores for an 80cm globe

Painting the World

Every day is different in the studio and as each globe and each stop of the process requires drying and resting time, we can work on multiple globes at once…

Painting final details

Varnishing a finished globe that will then go onto a handcrafted wooden base

We developed the roller bearing system, and have a number of people who do designs for me. Grenville Herrald (one of the team who designed the pods for the British Antarctic Survey) designed the curve and it is fabricated by heritage technicians from Aston Martin.

Varnishing an 80cm globe

Smiles.. working on the terrace on a summers day

Since we have almost 90,000 followers on Instagram and have gotten a fair bit of worldwide press (we are very lucky!), we have people emailing daily to come see the studio. If we kept our doors open like that we would never get any work done and all concentration would be lost, so we do have to limit visitors.

Multitasking

Everyone also brings up a Star Wars globe or a Mars globe or a Moon globe, but then when it comes to ordering…. they realise they would rather spend their money on a world globe as it has so much more detail.

Laying & manipulating the paper of the last gore going onto a 36cm handmade world globe

Photo by Stuart Freedman

Peter Bellerby

After the sphere is made, the next step is measuring out the distances and where the weight lays. All globes are weighted for the perfect spin. (Photo by Allun Callender)

Desk Globes

We still all use google maps / the map on our phones daily. The map we work on (daily still) is just a different kettle of fish completely. (Photo by Ana Santl)

Painting our largest globe, the 127cm Churchill

During WW2 Winston Churchill and Franklin D. Roosevelt were presented with two fifty inch globes, seen as a sign of friendship in an intensely difficult period of the war, and have since come to symbolise their owners; two important figures in our history. Our Churchill globe is very closely modeled on its original namesake in terms of appearance and size and combines the classic techniques used in the making of the original with the technology and durability of modern construction. We have plans to make just 40 at a rate of only one per year.

The largest globe we make next to the smallest

127cm Churchill next to a 23cm Mini Desk Globe.

159Kviews

Share on FacebookI really want to join you guys! I love drawing maps and stuff since I was little.

Thanks, you should keep it up!

Load More Replies...OMGosh what an experience just looking at and reading about Globe Making by Hand. This is an incredible talent/art that I hope never fades away! Such beautiful finished work is something I'd love to display in my home!!

Amazing, Beautiful, and Brilliant ! Bravo !! How wonderful to see the dedication and passion that goes into such incredible handiwork. But the word "handiwork" is inadequate by far.

This is absolutely fantastic! Not only are your globes breathtaking but the whole process you guys go through to create these works of art are beautiful. Thank you so much for sharing

Hi Chiemi, our website is www.bellerbyandco.com

Load More Replies...Incredible. Beautiful work encompassing art, history, geography, beauty. I'd love to own one.

What these people are doing it's tremendous, it's a meticulous job, but this is also seriously amazing. Handmade globes.

Thank you, very kind of you to say ;)

Load More Replies...Pretty interesting how Africa has been portrayed on maps: http://www.economist.com/blogs/dailychart/2010/11/cartography

Yes that's why people need globes. A globe is a true representation of the world, Africa and all. Things have to be distorted on a flat map unfortunately...

Load More Replies...In today's world its nice to see some of the old artisan ways still exist.

Oh my god just fall in love with the guy having black hair and gaze. Men in work are so attracted!

Check out #JonTheGlobemakerFanclub on Instagram, we like to embarrass him with attention ;)

Load More Replies...Thank you endlessly for having the wherewithal to undertake this enormous task - bravo!! A new dream....to own and share my very own Bellerby!

Your Globes are fantastic, but whoever writes the articles needs to polish up their grammar. Poor grammar lets your professionalism down.

I really want to join you guys! I love drawing maps and stuff since I was little.

Thanks, you should keep it up!

Load More Replies...OMGosh what an experience just looking at and reading about Globe Making by Hand. This is an incredible talent/art that I hope never fades away! Such beautiful finished work is something I'd love to display in my home!!

Amazing, Beautiful, and Brilliant ! Bravo !! How wonderful to see the dedication and passion that goes into such incredible handiwork. But the word "handiwork" is inadequate by far.

This is absolutely fantastic! Not only are your globes breathtaking but the whole process you guys go through to create these works of art are beautiful. Thank you so much for sharing

Hi Chiemi, our website is www.bellerbyandco.com

Load More Replies...Incredible. Beautiful work encompassing art, history, geography, beauty. I'd love to own one.

What these people are doing it's tremendous, it's a meticulous job, but this is also seriously amazing. Handmade globes.

Thank you, very kind of you to say ;)

Load More Replies...Pretty interesting how Africa has been portrayed on maps: http://www.economist.com/blogs/dailychart/2010/11/cartography

Yes that's why people need globes. A globe is a true representation of the world, Africa and all. Things have to be distorted on a flat map unfortunately...

Load More Replies...In today's world its nice to see some of the old artisan ways still exist.

Oh my god just fall in love with the guy having black hair and gaze. Men in work are so attracted!

Check out #JonTheGlobemakerFanclub on Instagram, we like to embarrass him with attention ;)

Load More Replies...Thank you endlessly for having the wherewithal to undertake this enormous task - bravo!! A new dream....to own and share my very own Bellerby!

Your Globes are fantastic, but whoever writes the articles needs to polish up their grammar. Poor grammar lets your professionalism down.

Dark Mode

Dark Mode

No fees, cancel anytime

No fees, cancel anytime

369

44