Hello Pandas! This was a neat project that came through the studio and I thought you might be interested to see the pieces and the process as a metalsmith, historian, and/or craftsman. I was entrusted with ancient Viking artifacts to reproduce copies for everyday enjoyment while the originals are kept safe.

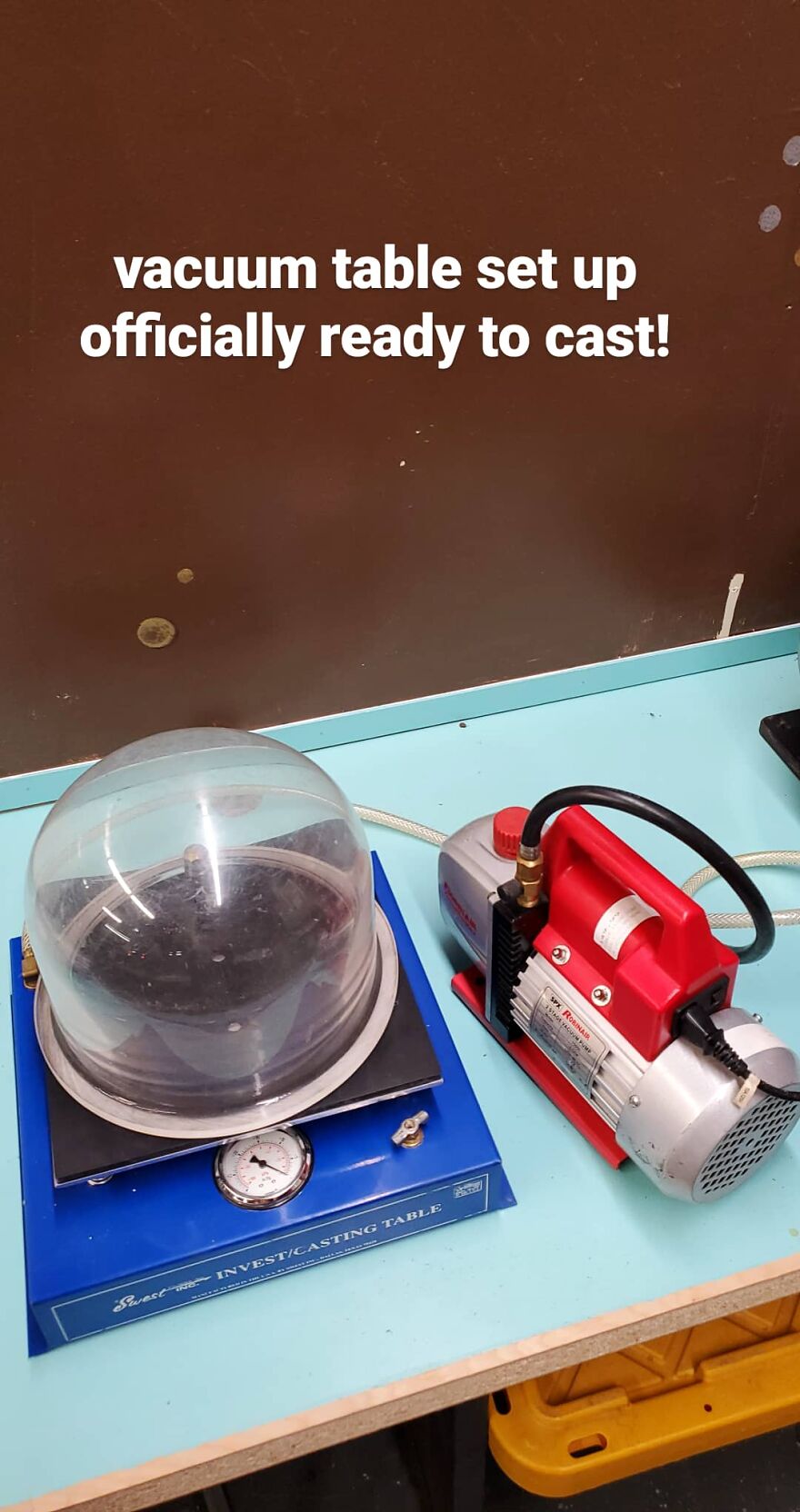

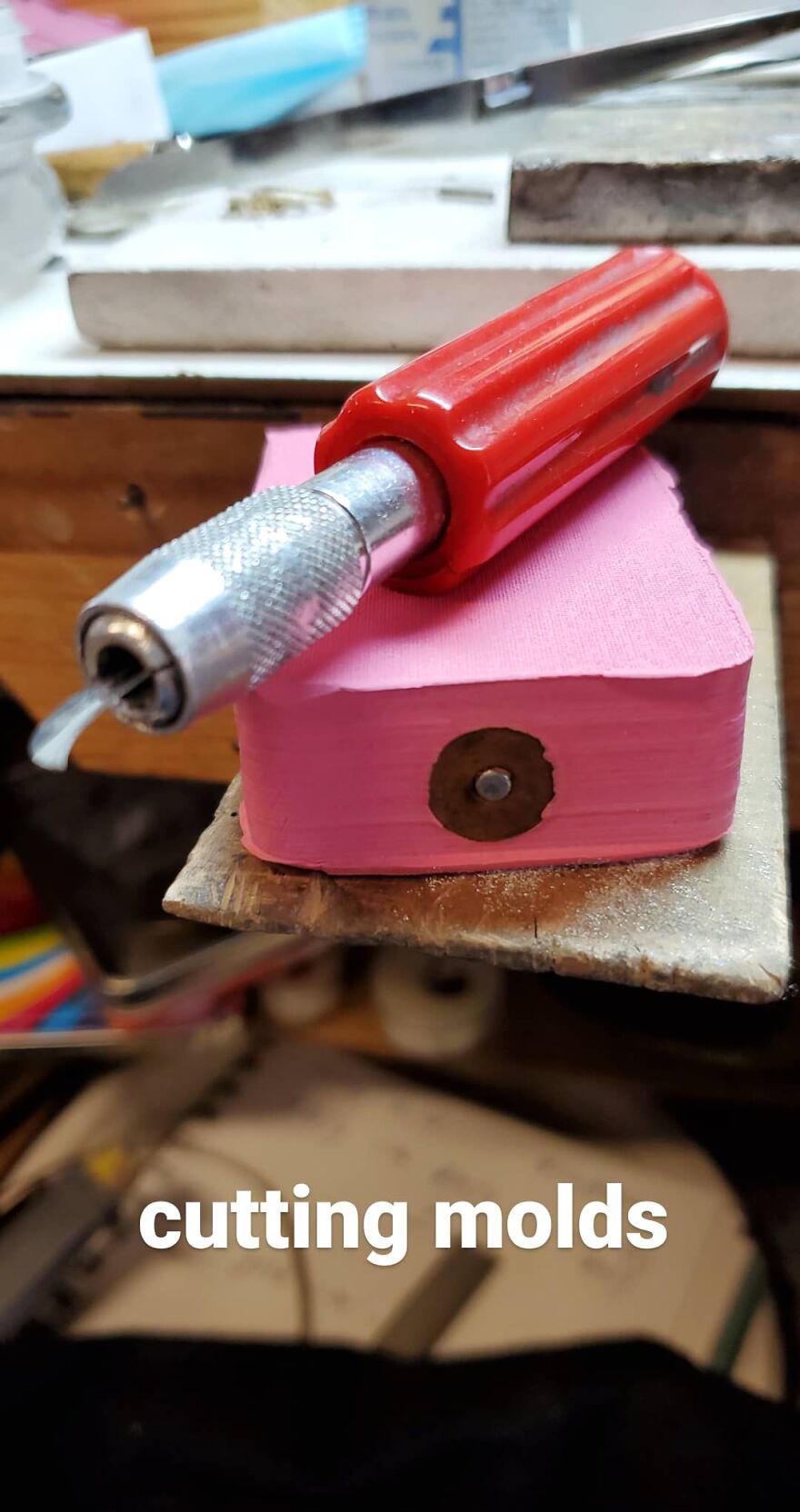

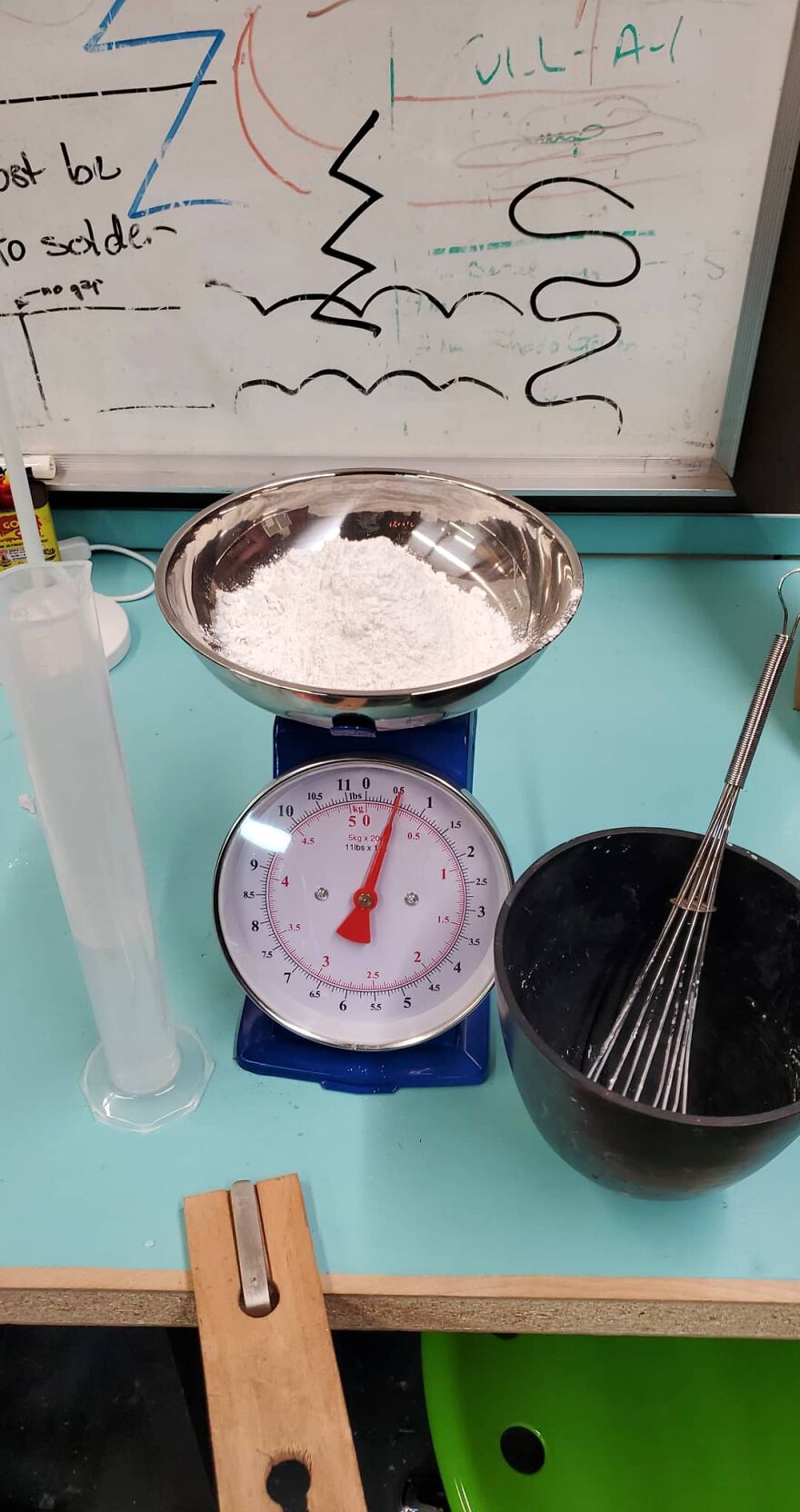

First, I made molds of the artifacts and cured them in the Vulcanizer. Next, I cut the molds and prepared them for wax injection. Once I had the waxes it was time to sprue them up and weigh the trees to calculate the amount of metal needed to cast. Next, the investment was prepared, vacuumed, and poured. The next day the flasks went through burnout cycle in the kiln until ready to cast.

Once cast, you will see the trees fresh out of the quench. I used my portable pressure washer to clean up the castings and the flasks. The trees were put in pickle solution to de-oxidize and then vibratory tumbled overnight. After tumbling the sprues are cut off and finishing begins.

Overall, (5) different artifacts were re-produced: Thor’s Hammer, Fafnir, Lunar Mask, Hammer, and a Cross. This job was very meaningful to the client, and, for me, it was an amazing honor to be the next set of hands to work on these pieces. If only a conduit could open and I catch a glimpse back in time…

Hammers + Crosses

Ready, set, GO! 12/10 still terrifying.

Fafnir

Thor’s Hammer

Casting grain, ready to melt

investment

thank you! i think about that daily in the challenges i face as a modern goldsmith. what we do is difficult today, i often wonder how ancient jewelers did some of things they did!

Load More Replies...thank you! i think about that daily in the challenges i face as a modern goldsmith. what we do is difficult today, i often wonder how ancient jewelers did some of things they did!

Load More Replies...

2

3